Description

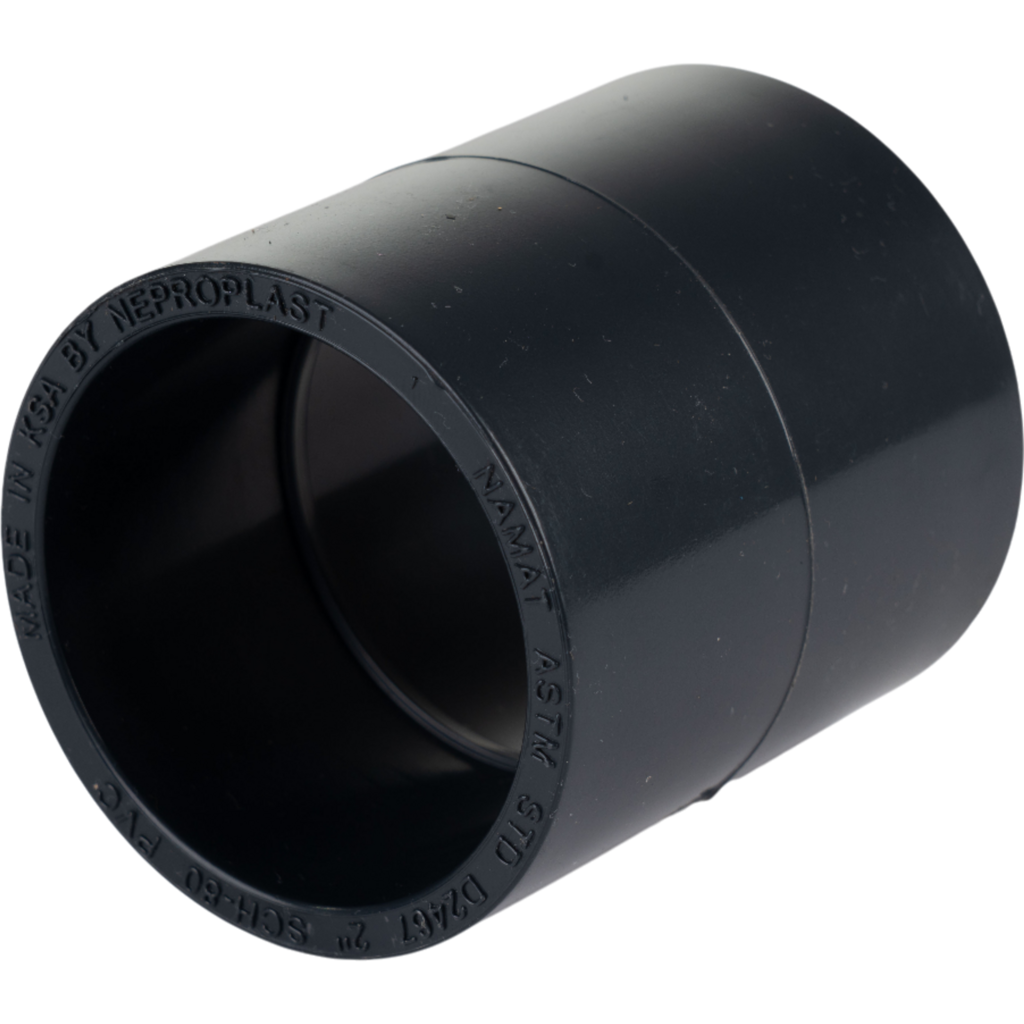

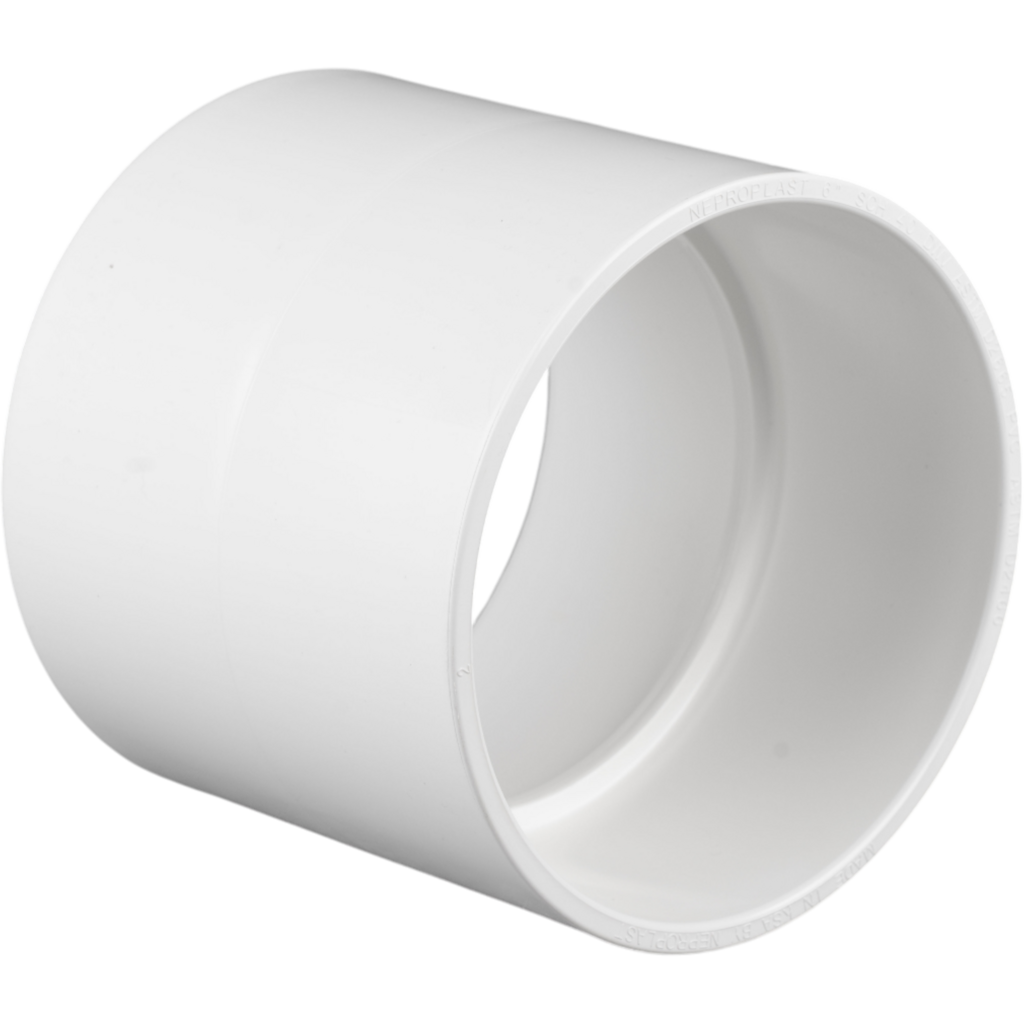

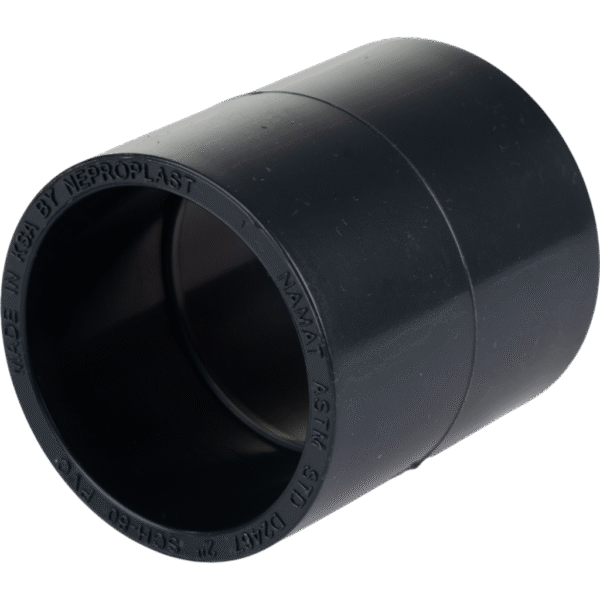

التصميم والوظيفة:

- Standard Coupling (Register Coupling): يوفر وصلة ثابتة ودائمة بين أنبوبين من PVC، مع ضمان المحاذاة والتدفق المستمر بدون انقطاع.

- Repair Coupling (Slip Coupling): يحتوي على مقابس ممتدة بدون توقف مركزي، مما يسمح للتركيب بالانزلاق على الأنبوب لإصلاح أو استبدال سريع.

المادة ولون الكود:

PVC (Polyvinyl Chloride): صلب، مقاوم للتآكل، وقوي ميكانيكيًا.

لون الكود:

- أبيض: Schedule 40، يُستخدم عادةً لتطبيقات الضغط القياسية وغير الضغطية.

- رمادي: Schedule 80، مصمم للأنظمة ذات الضغط الأعلى والتي تتطلب سماكة أكبر للأنبوب وقوة إضافية.

الامتثال للمعايير:

- ASTM D 2466: تركيبات ضغط Schedule 40.

- ASTM D 2467: تركيبات ضغط Schedule 80.

- ASTM D 2665: تركيبات الصرف والمياه العادمة والتهوية (DWV).

خصائص الأداء:

- مستويات الضغط: تعتمد على الجدولSchedule 40 أو Schedule 80 وحجم الأنبوب.

- نطاق درجة الحرارة: تشغيل مستمر حتى 60°C

- الختم: متوافق مع PVC solvent cement لوصلات دائمة وخالية من التسرب.

- عمر الخدمة: أكثر من 50 عامًا في ظل ظروف التشغيل القياسية.

التطبيقات:

- شبكات مياه الشرب وتوزيعها.

- أنظمة الصرف والمياه العادمة والتهوية (DWV).

- شبكات الأنابيب الصناعية والمرافق.

- إصلاح وتوسيع الأنابيب دون الحاجة لإعادة تصميم النظام.

التركيب:

- Standard Couplings: تثبت باستخدام solvent cement وفق معايير ASTM للحصول على وصلات دائمة ومحاذاة صحيحة.

- Repair Couplings: تنزلق على أجزاء الأنبوب المحضرة وتثبت بـ solvent cement لاستعادة الخدمة بسرعة.

الفوائد الرئيسية:

- يحافظ على استمرارية التدفق ويوفر وصلات موثوقة وخالية من التسرب.

- مادة صلبة ومقاومة للتآكل لضمان عمر طويل.

- مرمزة بالألوان لتسهيل التعرف على أنظمة Schedule 40 وSchedule 80.

- تركيب سريع وسهل، يقلل من الوقت والجهد المطلوبين.

| Item Code | Description |

|---|---|

| SN.M112 | 1.1/2" Coupling Sch-40 |

| SN.M114 | 1.1/4" Coupling Sch-40 |

| SN.M2 | 2" Coupling Sch-40 |

| SN.M1 | 1" Coupling Sch-40 |

| SN.M12 | 1/2" Coupling Sch-40 |

| SN.M34 | 3/4" Coupling Sch-40 |

| SN-M12 | 1/2" Coupling Sch-80 |

| SN-M34 | 3/4" Coupling Sch-80 |

| SN-M6 | 6" COUPLING SCH80 PV |

| SN-M3 | 3" Coupling SCH80 PV |

| SN-M4 | 4" Coupling SCH80 PV |

| SN-M112 | Sch-80 Coupling 1.1/ |

| SN-M2 | Sch-80 Coupling 2" |

| SN-M114 | Sch-80 Coupling 1.1/ |

| SN-M8 | 8" Coupling PVC SCH80 |

| SNVM3 | DWV COUPLING 3’’ |

| SNWM6 | DWV Coupling 6" |

| SNVM8 | 8’’ COUPLING ASTM D2665 DWV PVC |

| SN-M1 | 1" Coupling Sch-80 |

For more information about this product and its related items, you may check and browse the catalog below:

المراجعات

لا توجد مراجعات بعد.