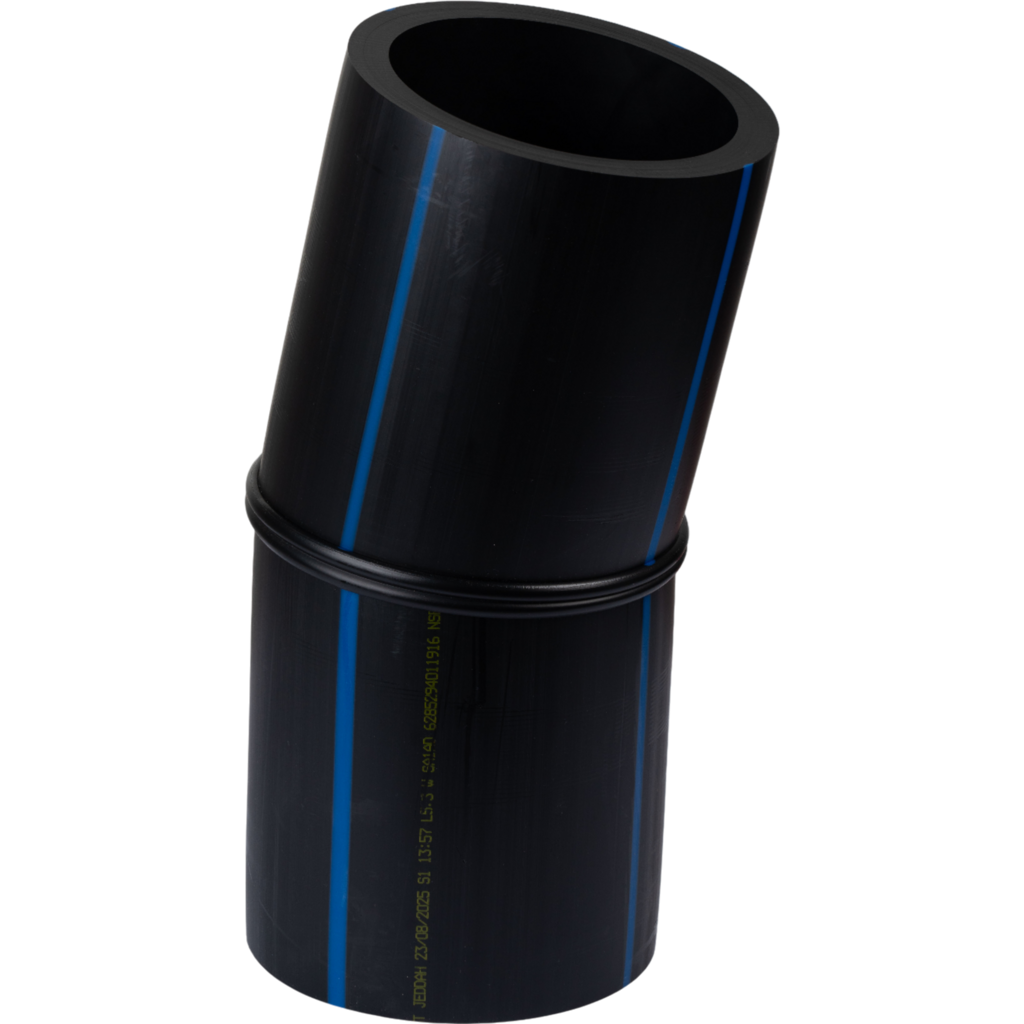

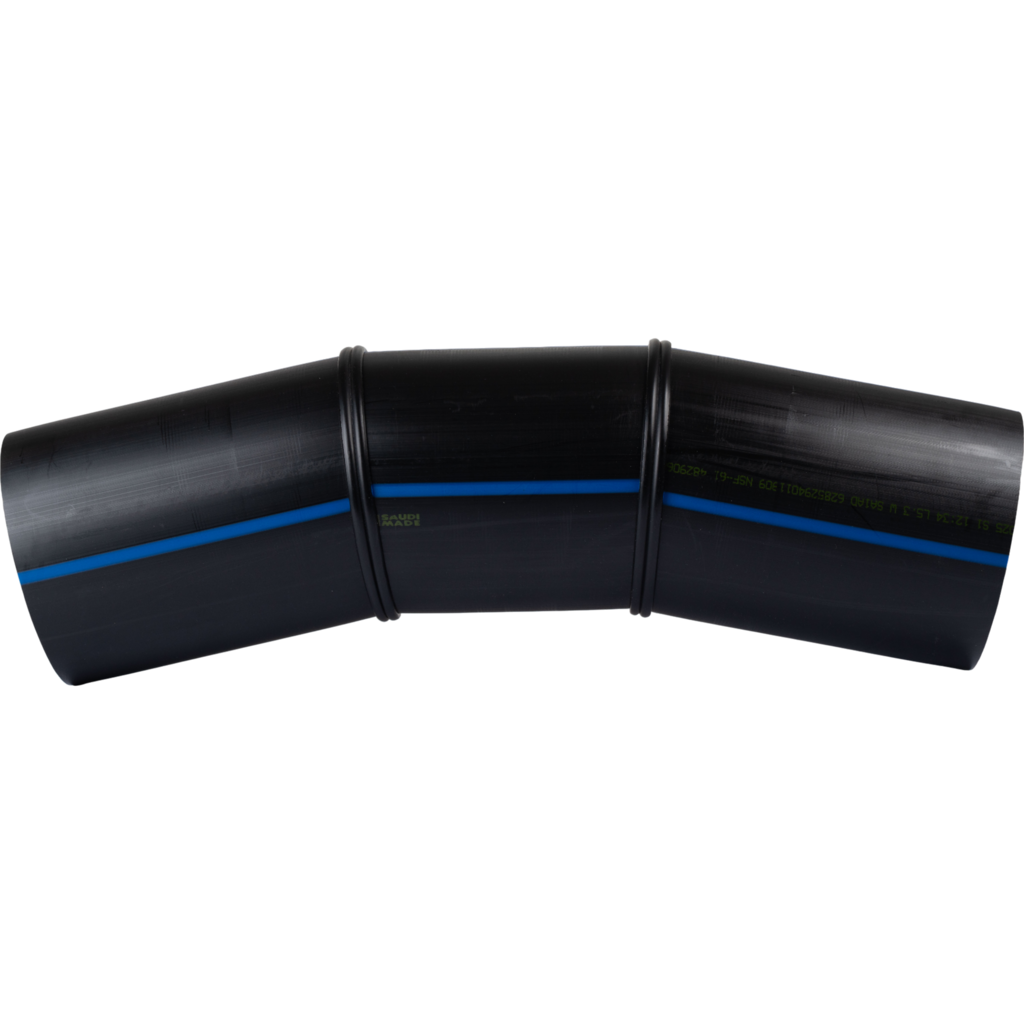

Description

المواد والتصنيع:

- مصنوعة من HDPE (PE100) – قوة شد عالية، مقاومة كيميائية، وقدرة تحمل للصدمات.

- يتم تصنيعها باستخدام تقنية اللحام بالضغط (Butt Welding) لضمان سمك جدار موحد، قوة متسقة، وأداء طويل الأمد.

- عملية التصنيع تتم باستخدام آلات متخصصة من موردين دوليين رائدين، لضمان محاذاة دقيقة، وصلات اندماج مثالية، وصلابة ميكانيكية فائقة.

الخصائص الفنية:

- الامتثال للمعايير: ISO 4427-3 – أنظمة أنابيب البولي إيثيلين لتوزيع المياه – التركيبات.

- الزوايا: متوفرة بـ 11.25°، 22.5°، 30°، 45°، 60°، و90°، أو حسب متطلبات المشروع.

- طريقة الربط: لحام بالضغط باستخدام حرارة مضبوطة وضغط اندماج لضمان وصلات سلسة وخالية من التسرب.

- مستوى الضغط: متوافق مع أنظمة PN 6، PN 10، PN 16، وPN 20 حسب سلسلة الأنابيب (SDR).

خصائص الأداء:

- متانة هيكلية ممتازة ضد الضغط الداخلي والأحمال الخارجية.

- مقاومة فائقة للتآكل والاحتكاك في التربة والسوائل العدوانية.

- سطح داخلي أملس يقلل فقد الاحتكاك ويحافظ على كفاءة التدفق.

- عمر خدمة طويل يتجاوز 50 عامًا تحت ظروف التشغيل القياسية.

التطبيقات:

- أنظمة مياه الشرب ومياه الصرف الصحي.

- أنابيب صناعية ومعالجة السوائل.

- شبكات الري والبنية التحتية للخدمات.

- التركيبات تحت الأرض وفوق الأرض التي تتطلب تغييرات اتجاه مخصصة.

الفوائد:

- تصميم قابل للتخصيص بالكامل لتلبية احتياجات توجيه المشروع الخاصة.

- وصلات اندماج متجانسة تلغي نقاط التسرب المحتملة.

- متانة ومرونة عالية، مناسبة للتركيبات الديناميكية والمدفونة.

- تصنيع تحت رقابة صارمة لضمان أداء موثوق ومتسق.

المراجعات

لا توجد مراجعات بعد.