Description

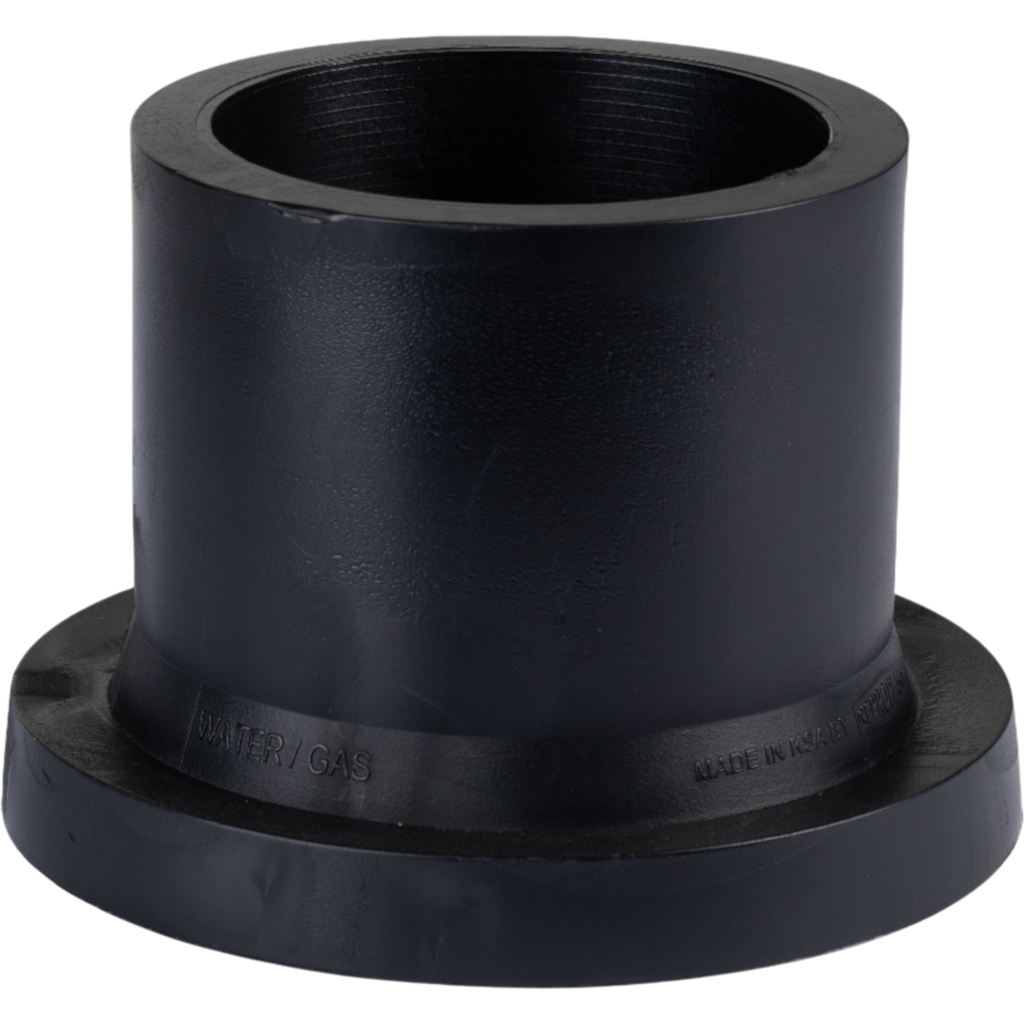

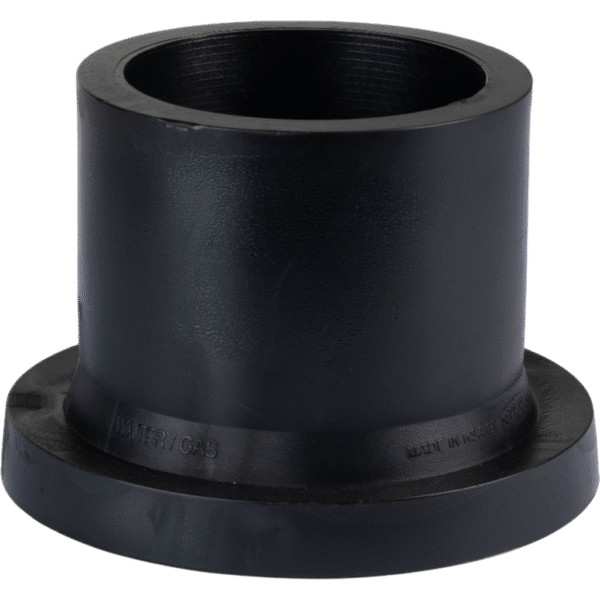

التصميم والبنية:

يتكون Stub End من جزئين:

- Spigot End – نهاية عادية للحام بالانصهار (Butt Fusion) أو اللحام الكهربائي (Electrofusion) مع أنابيب HDPE.

- Lap End (Flared Face) – نهاية مفلطحة تتصل بحلقة دعم أو فلانجة فضفاضة (Backing Ring/Flange).

عند استخدامه مع حلقة دعم معدنية أو HDPE، تتحمل النهاية المفلطحة الضغط الختم، بينما توفر الحلقة الدعم الميكانيكي للربط بالبراغي.

خصائص المادة:

- مصنوعة من High-Density Polyethylene (HDPE) PE100 وفق معايير ISO 4427 / DIN 8077/8078.

- مقاومة للتآكل والاحتكاك ومعظم المواد الكيميائية.

- مرونة عالية ومقاومة للصدمات، مناسبة للتركيبات تحت الأرض وفوق الأرض.

- غير سامة وآمنة لتطبيقات مياه الشرب.

الخصائص التشغيلية:

- ضغط التشغيل: عادة مصممة لـ PN6، PN10، PN16 أو أعلى (حسب حجم الأنبوب والفلانجة).

- مدى درجة الحرارة: -40°C إلى +60°C للخدمة المستمرة ذروات قصيرة تصل إلى 80°C حسب الوسط.

- سلامة الوصل: توفر وصلة قوية وخالية من التسرب عند استخدامها مع الحشوات والفلانجات المناسبة.

- عمر الخدمة: أكثر من 50 سنة تحت ظروف التشغيل العادية.

التطبيقات:

- شبكات إمداد وتوزيع المياه.

- نقل السوائل الصناعية والكيميائية.

- أنابيب الصرف الصحي والمياه العادمة.

- أنابيب بحرية وأعمال التجريف.

- الحالات التي تتطلب فكًا متكررًا أو ضبط محاذاة الفلانجات.

التركيب:

- يتم لحام Stub End بالأنبوب باستخدام تقنيات Butt Fusion أو Electrofusion.

- توضع حلقة دعم معدنية أو HDPE فوق النهاية المفلطحة وتُثبت بالبراغي لإنشاء وصلة الفلانجة.

- سهوله الفك دون قطع الأنبوب، مما يجعلها اقتصادية للصيانة.

| Item Code | Description |

|---|---|

| 925ENFB09Q110 | 110mm Stub end long neck SDR09 |

| 925ENFB11Q110 | 110mm Stub end long neck SDR11 |

| 925ENFB11Q160 | 160mm Stub end long neck SDR11 |

| 925ENFB11Q200 | 200mm Stub end long neck SDR11 |

| 925ENFB11Q250 | 250mm Stub end long neck SDR11 |

| 925ENFB11Q315 | 315mm Stub end long neck SDR11 |

| 925ENFB11Q063 | 63mm Stub end long neck SDR11 |

| 925ENFB09Q160 | 160mm Stub end long neck SDR09 |

| 925ENFB09Q200 | 200mm Stub end long neck SDR09 |

| 925ENFB09Q250 | 250mm Stub end long neck SDR09 |

| 925ENFB09Q315 | 315mm Stub end long neck SDR09 |

| 925ENFB09Q063 | 63mm Stub end long neck SDR09 |

المراجعات

لا توجد مراجعات بعد.