Our Facilities

- Home

- /

- Our Facilities

Our Manufacturing Facilities

We have six production facilities operating in two industrial areas, in Jeddah Saudi Arabia, with a total of 144 production lines, covering a total space of around 129,000 sqm, supported with material mixing facilities, with automatic distribution systems.

Our extrusion production lines consist of 66, and a total of 68 injection molding lines , producing an annual capacity of 204,000 metric tons using top European machinery brands. We are continuously expanding our capacity and product range to meet growing market demand.

Our facilities are also equipped with the latest tools and technologies to guarantee superior quality standards.

Our CNC Department at Neproplast plays a pivotal role in supporting the production operation by ensuring rapid, precise maintenance for our production cycle. The CNC Department is equipped with advanced technologies that enable us to fabricate and repair critical components of injection molds and extrusion lines.

With a total area of 15,500 sqm, our new logistics warehouse for raw materials plays a vital role in ensuring smooth and seamless factory operations. It guarantees consistent material availability, supports efficient inventory control, and enhances safety by complying with storage regulations for hazardous or sensitive items. As Neproplast’s factories continue to grow, the warehouse enables scalable expansion and multi-site coordination—making it a strategic asset for long-term success.

Pipe Extrusion Facility PVC

- 26 Production lines

- Operating 24/7

- Automated raw material feeding system

- Usage of organic materials during the production process.

- Annual capacity: 102,000 metric tons

- Sizes in Metric: 20mm to 710 mm

- Sizes In Inches : ½ Inch to 8 inches.

Pipe Extrusion Facility – CPVC

- 9 Production lines

- Operating 24/7

- Annual capacity: 25,000 metric tons

- Sizes: ½ Inch to 8 inches

Pipe Extrusion Facility – HDPE

- 10 Production lines, equipped with large coilers.

- Operating 24/7

- Annual capacity: 48,000 metric tons

- Sizes: 20 mm to 1600 mm

Pipe Extrusion Facility – HDPE TELECOM

- 18 production lines

- Operating 24/7

- Annual Capacity: 7,000 metric tons

- Size: 75mm to 120 mm (COD)

- Microduct:10 mm to 28 mm with 2-way up to 7-way design

- Miniduct: 20 mm to 42mm

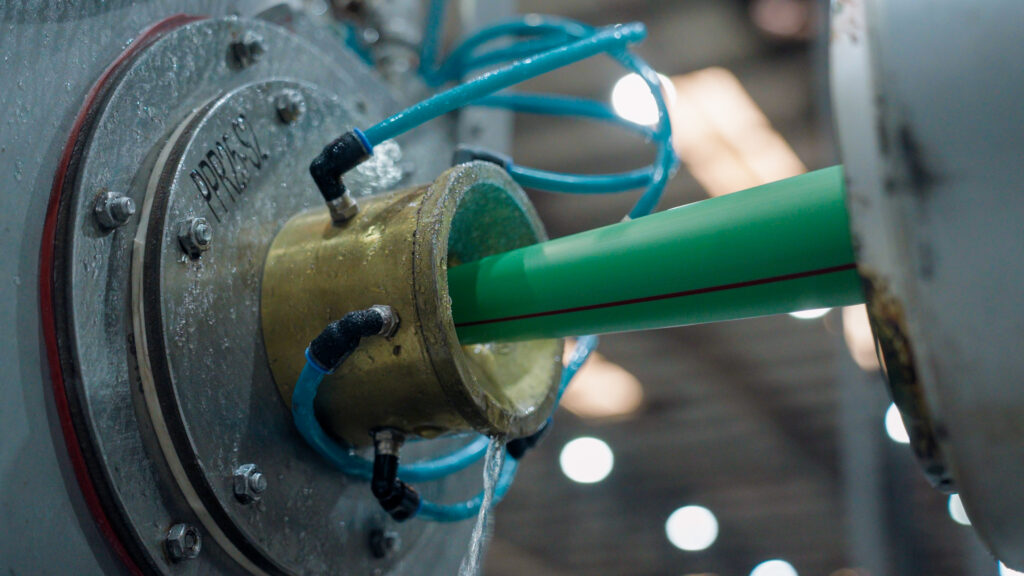

Pipe Extrusion Facility – PPR

- 3 Production lines

- Operating 24/7

- Annual capacity: 5,000 metric tons

- Sizes: from 20 mm up to 110 mm

In our dedicated facility, we specialize in fabricating and customizing pipes and fittings to meet specific customer requirements and evolving market demands

Injection Molding Facility – PVC, CPVC, PPR & HDPE

- 68 production lines

- Operating 24/7

- Annual Capacity: 17,000 metric tons

- Automated raw material feeding system

- Robotic system for product handling

Laboratory

- 3 quality control laboratories

- Operating 24/7 to support production.

- Quality control checks and inspection for all production and raw materials

- Following Saudi and international standards

Logistic Raw Material Warehouse

- A resilient supply chain operation to meet national and international production needs.

- Facilitates multi-site coordination

- Ensures a steady supply of raw materials, guaranteeing on time delivery.

- Designed to meet and comply with safety standards.

Tools Workshop

- Operating 24/7 to support production. Ensuring uninterrupted support for production lines across all shifts.

- A strategic enabler, supplying precision tools, dies, and molds that keep operations running smoothly and consistently.

CNC Facility

- 9 Machines

- The machines allow us to perform a wide range of operations, including milling, turning, wire cutting, and sinking, all essential for maintaining and enhancing our injection molds and extrusion tooling.

- Precision and Quality: Our machines deliver high-accuracy parts that meet our production specifications.

- Flexibility: We can handle a wide range of part geometries and materials, adapting to evolving production needs.

- Designed to provide us with an in-house facility for a more adaptive and responsive solution.