Description

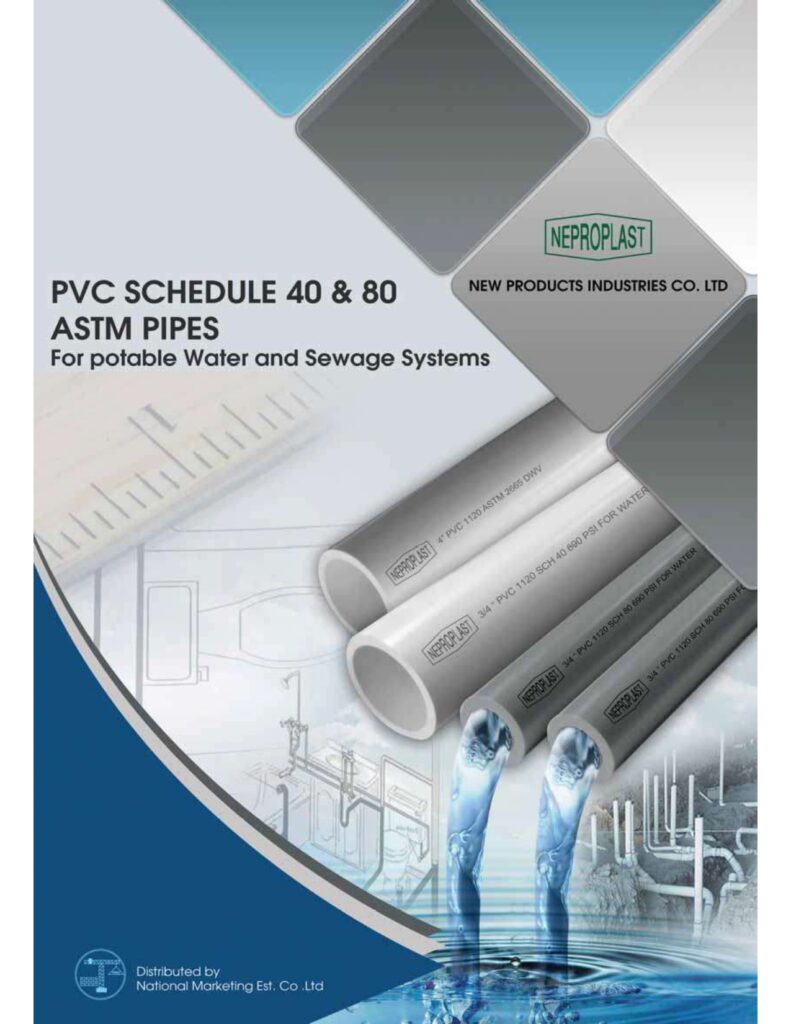

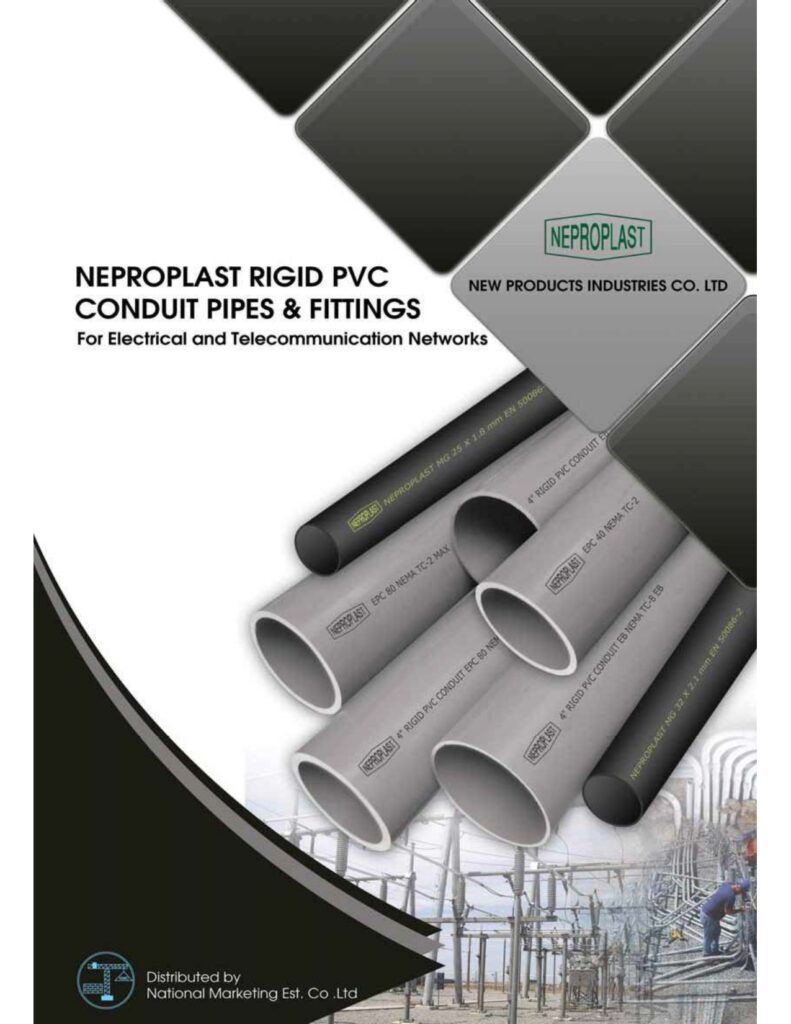

Neproplast PVC pipes are manufactured to international standards such as ASTM D 1785, ASTM D 2241, ASTM D 2665, and NEMA TC, ensuring durability and reliability in various applications. Available in white and gray, these pipes are widely used in pressure systems, drainage networks, and electrical conduits. With their smooth internal surfaces, they reduce friction losses, while their resistance to chemicals and corrosion makes them a cost-effective choice for long-term performance.

ASTM D 1785 – Standard Specification for PVC Plastic Pipe, Schedules 40, and 80

Overview:

ASTM D 1785 is a widely recognized standard for rigid polyvinyl chloride (PVC) pipes used in pressure applications and conduit systems. It specifies the physical, mechanical, and dimensional requirements for PVC pipes, ensuring they can safely handle fluid transport under pressure as well as electrical conduit installations.

Technical Details:

Pipe Schedules: Defines two schedules—Schedule 40, and Schedule 80 —each indicating different wall thicknesses and pressure ratings.

Schedule 40: Standard wall thickness for moderate pressure.

Schedule 80: Thicker walls for higher pressure applications.

Material Requirements:

Made from PVC Type I, Grade 1 or equivalent.

Must have high chemical resistance, low water absorption, and good dimensional stability.

- Pressure Ratings:

- Pipes are rated for pressure-temperature relationships; Schedule 40 pipes may handle pressures up to 19 bar at 23°C (varies by diameter and wall thickness).

Dimensions & Tolerances:

Specifies outside diameter (OD), wall thickness, and length tolerances to ensure consistent fit for threaded or socketed connections.

Performance Requirements:

Hydrostatic strength: Pipes must withstand long-term internal pressures without failure.

Impact resistance: Must resist cracking under typical handling and installation stresses.

Applications:

Water supply systems under pressure.

Electrical conduits for building wiring.

Industrial chemical lines where moderate pressure piping is needed.

Advantages:

Lightweight and easy to handle.

High chemical and corrosion resistance.

Smooth inner surface reduces friction losses, improving flow efficiency.

| Outer Diameter (inch) | Schedule 40 Wall Thickness (mm) | Schedule 40 Color | Schedule 80 Wall Thickness (mm) | Schedule 80 Color | Standard |

|---|---|---|---|---|---|

| 1/2" | 2.77 | White | 3.73 | Gray | ASTM D 1785 |

| 3/4" | 2.87 | White | 3.91 | Gray | ASTM D 1785 |

| 1" | 3.38 | White | 4.55 | Gray | ASTM D 1785 |

| 1 1/4" | 3.56 | White | 4.85 | Gray | ASTM D 1785 |

| 1 1/2" | 3.68 | White | 5.08 | Gray | ASTM D 1785 |

| 2" | 3.91 | White | 5.54 | Gray | ASTM D 1785 |

| 2 1/2" | 5.16 | White | 7.01 | Gray | ASTM D 1785 |

| 3" | 5.49 | White | 7.62 | Gray | ASTM D 1785 |

| 3 1/2" | 5.74 | White | 8.08 | Gray | ASTM D 1785 |

| 4" | 6.02 | White | 8.56 | Gray | ASTM D 1785 |

| 5" | 6.55 | White | 9.52 | Gray | ASTM D 1785 |

| 6" | 7.11 | White | 10.97 | Gray | ASTM D 1785 |

| 8" | 8.2 | White | 12.7 | Gray | ASTM D 1785 |

ASTM D 2241 – Standard Specification for Polyvinyl Chloride (PVC) Plastic Pressure-Rated Pipe (SDR Series)

Overview:

ASTM D 2241 defines the requirements for PVC pressure pipes, primarily used in water distribution, irrigation, and other pressure-based applications. The standard introduces SDR (Standard Dimension Ratio) ratings, which relate the pipe’s outside diameter (OD) to wall thickness, allowing engineers to select pipes based on the required pressure rating and pipe size.

Technical Details:

SDR Rating:

The SDR value = OD ÷ Wall Thickness.

Lower SDR values indicate thicker walls and higher pressure capability, while higher SDR values are thinner and suitable for lower pressures.

Common SDR ratings: SDR 17, SDR 21, SDR 26, etc.

Material Requirements:

Made from rigid PVC (Type I, Grade 1) with consistent chemical composition for strength and durability.

Must exhibit resistance to corrosion, chemicals, and UV degradation (if exposed).

Dimensions & Tolerances:

OD and wall thickness must comply with SDR-based tolerances for consistent fit with fittings and joints.

Pipe lengths are standardized, typically 10–20 feet, depending on manufacturer and application.

Performance Requirements:

Hydrostatic Pressure Rating: Pipes are rated for continuous pressure service at 23°C, e.g., an SDR 17 pipe may handle up to 14 bar.

Impact Resistance: Pipes must resist cracking under handling and installation stress.

Long-Term Strength: Designed for sustained operation under continuous pressure without deformation or failure.

Long-Term Strength: Designed for long service life under continuous pressure.

Applications:

Water supply pipelines for potable water and irrigation systems.

Industrial pressure piping, including chemical transport lines.

Sewer and stormwater systems under pressure conditions.

Advantages:

Lightweight and easy to install with solvent-weld or gasketed joints.

Smooth internal surface reduces friction loss, improving flow efficiency.

High chemical and corrosion resistance ensures long-term reliability.

SDR system allows precise selection of pressure capacity based on wall thickness.

| Outer Diameter (inch) | SDR 13.5 Wall Thickness (mm) | SDR 13.5 Color | SDR 17 Wall Thickness (mm) | SDR 17 Color | SDR 21 Wall Thickness (mm) | SDR 21 Color | SDR 26 Wall Thickness (mm) | SDR 26 Color | SDR 32.5 Wall Thickness (mm) | SDR 32.5 Color | SDR 41 Wall Thickness (mm) | SDR 41 Color | SDR 46 Wall Thickness (mm) | SDR 46 Color | Standard |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.57 | White | ASTM D 2241 | ||||||||||||

| 3/4" | 1.98 | White | 1.57 | White | 1.52 | White | ASTM D 2241 | ||||||||

| 1" | 2.46 | White | 1.96 | White | 1.60 | White | 1.52 | White | ASTM D 2241 | ||||||

| 1 1/4" | 3.12 | White | 2.49 | White | 2.01 | White | 1.62 | White | 1.52 | White | ASTM D 2241 | ||||

| 1 1/2" | 3.58 | White | 2.84 | White | 2.29 | White | 1.85 | White | 1.52 | White | ASTM D 2241 | ||||

| 2" | 4.47 | White | 3.56 | White | 2.87 | White | 2.31 | White | 1.85 | White | ASTM D 2241 | ||||

| 2 1/2" | 5.41 | White | 4.29 | White | 3.48 | White | 2.79 | White | 2.24 | White | ASTM D 2241 | ||||

| 3" | 6.58 | White | 5.23 | White | 4.24 | White | 3.43 | White | 2.74 | White | 2.16 | White | ASTM D 2241 | ||

| 3 1/2" | 7.52 | White | 5.97 | White | 4.83 | White | 3.91 | White | 3.12 | White | 2.49 | White | ASTM D 2241 | ||

| 4" | 8.46 | White | 6.73 | White | 5.43 | White | 4.39 | White | 3.50 | White | 2.79 | White | 1.78 | White | ASTM D 2241 |

| 6" | 12.47 | White | 9.91 | White | 8.03 | White | 6.48 | White | 5.18 | White | 4.11 | White | 2.64 | White | ASTM D 2241 |

| 8" | 12.90 | White | 10.41 | White | 8.43 | White | 6.73 | White | 5.33 | White | 3.43 | White | ASTM D 2241 |

ASTM D 2665 – Standard Specification for Polyvinyl Chloride (PVC) Plastic Pipe, Schedule 40 for DWV (Drain, Waste, and Vent)

Overview:

ASTM D 2665 specifies requirements for PVC pipes used in drain, waste, and vent (DWV) systems, which are primarily non-pressurized or low-pressure applications. It ensures pipes are durable, dimensionally accurate, and suitable for typical household and industrial wastewater and venting systems.

Technical Details:

Pipe Schedule:

Schedule 40: Standard wall thickness, ideal for most residential and commercial drainage applications.

Material Requirements:

Made from rigid PVC (Type I, Grade 1).

Chemically resistant against acids, alkalis, and common household or industrial chemicals present in waste streams.

Dimensions & Tolerances:

Specifies outside diameter (OD), wall thickness, and length tolerances for proper solvent-welded connections.

Ensures dimensional consistency for reliable socketed connections in DWV systems.

Performance Requirements:

Impact Resistance: Resists cracking during shipping, handling, and installation, even at low temperatures.

Flexural Strength: Maintains structural integrity under typical installation stresses.

Solvent Cement Compatibility: Joins reliably with standard PVC solvent cement for leak-proof connections.

Applications:

Residential, commercial, and industrial drainage networks.

Wastewater piping for sinks, toilets, showers, and floor drains.

Vent stacks in buildings to ensure proper airflow and drainage.

Advantages:

Lightweight and easy to cut and install.

Corrosion and chemical resistant, extending service life.

Smooth internal surface minimizes clogging and supports efficient wastewater flow.

Fire-retardant compared to some other plastic piping materials.

| Outer Diameter (inch) | Schedule 40 Wall Thickness (mm) | Color | Standard |

|---|---|---|---|

| 1 1/4" | 3.56 | White | ASTM D 2665 |

| 1 1/2" | 3.68 | White | ASTM D 2665 |

| 2" | 3.91 | White | ASTM D 2665 |

| 3" | 5.49 | White | ASTM D 2665 |

| 4" | 6.02 | White | ASTM D 2665 |

| 6" | 7.11 | White | ASTM D 2665 |

| 8" | 8.20 | White | ASTM D 2665 |

NEMA TC – PVC Electrical Conduit Pipes

Overview:

NEMA TC specifies standards for rigid PVC conduit pipes designed to safely house and protect electrical wiring. The standard ensures mechanical strength, dimensional accuracy, and long-term durability for indoor and outdoor conduit applications.

Technical Details:

Material Requirements:

Manufactured from rigid PVC with high chemical resistance and flame-retardant properties.

Provides excellent electrical insulation.

Dimensions & Tolerances:

Standardized outside diameter (OD), wall thickness, and pipe lengths for compatibility with fittings.

Available in Schedule 40 (standard wall) and Schedule 80 (thick wall).

Performance Requirements:

Impact Resistance: Pipes resist cracking or deformation during handling and installation.

Temperature Rating: Suitable for continuous use up to 60°C, short-term up to 75°C.

Mechanical Strength: Maintains structural integrity under standard bending, pulling, and external load conditions.

Advantages:

Lightweight and easy to handle.

Smooth internal surface facilitates cable pulling.

Corrosion and chemical-resistant for long-term durability.

| Outer Diameter (inch) | EPC-80 NEMA TC-2 Wall Thickness (mm) | EPC-80 NEMA TC-2 Color | EPC-40 NEMA TC-2 Wall Thickness (mm) | EPC-40 NEMA TC-2 Color | EPT-A NEMA TC-2 Wall Thickness (mm) | EPT-A NEMA TC-2 Color | NEMA TC-6 EB Wall Thickness (mm) | NEMA TC-6 EB Color | NEMA TC-6 DB Wall Thickness (mm) | NEMA TC-6 DB Color | NEMA TC-8 EB Wall Thickness (mm) | NEMA TC-8 EB Color | NEMA TC-8 DB Wall Thickness (mm) | NEMA TC-8 DB Color | Standard |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 3.73 | Gray | 2.77 | Gray | 1.52 | Gray | NEMA TC | ||||||||

| 3/4" | 3.91 | Gray | 2.87 | Gray | 1.52 | Gray | NEMA TC | ||||||||

| 1" | 4.55 | Gray | 3.38 | Gray | 1.52 | Gray | 1.52 | Gray | NEMA TC | ||||||

| 1 1/4" | 4.85 | Gray | 3.56 | Gray | 1.78 | Gray | NEMA TC | ||||||||

| 1 1/2" | 5.08 | Gray | 3.68 | Gray | 2.03 | Gray | 1.52 | Gray | NEMA TC | ||||||

| 2" | 5.54 | Gray | 3.91 | Gray | 2.54 | Gray | 1.52 | Gray | 1.52 | Gray | 1.52 | Gray | 1.96 | Gray | NEMA TC |

| 2 1/2" | 7.01 | Gray | 5.16 | Gray | 3.18 | Gray | NEMA TC | ||||||||

| 3" | 7.62 | Gray | 5.49 | Gray | 3.18 | Gray | 1.55 | Gray | 2.34 | Gray | 1.93 | Gray | 3.00 | Gray | NEMA TC |

| 4" | 8.56 | Gray | 6.02 | Gray | 3.81 | Gray | 2.08 | Gray | 3.07 | Gray | 2.54 | Gray | 3.91 | Gray | NEMA TC |

| 5" | 9.52 | Gray | 6.55 | Gray | 2.62 | Gray | 3.86 | Gray | 3.20 | Gray | 4.85 | Gray | NEMA TC | ||

| 6" | 10.97 | Gray | 7.11 | Gray | 3.18 | Gray | 4.62 | Gray | 3.86 | Gray | 5.77 | Gray | NEMA TC | ||

| 8" | 12.7 | Gray | 8.2 | Gray | NEMA TC |

For more information about this product and its related items, you may check and browse the catalog below:

Reviews

There are no reviews yet.